|

Demy (D&M) Bearing Co., Ltd.

|

Rolling Roll Bearings

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

This type of Bearings exhibits the performance with double-row tapered roller bearings,However,in comparison withd double-row tapered roller bearings

product name: Extra Large Rolling Roll Bearings

Rolling Mill Bearings

This type of Bearings exhibits the performance with double-row tapered roller bearings,However,in comparison with double-row tapered roller bearings,these bearings carry more larger radial load and have lower limit speed.Therefore,they are mainly applied in heavy machinery and rolling mills etc.

ROLLING MILL BEARINGS

Four-row Tapered Roller Bearings

This type of bearing exhibits the same performance with double-row tapered roller bearings.However,in comparison with double-row tapered roller bearings,these bearings carry more larger radial load and have lower limit speed.Therefore,they are mainly applied in heavy machinery and rolling mills etc.

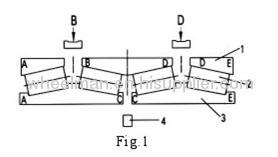

This type of bearing is suitable for low-speed and medium-speed rolling mills.The internal clearance is pre-adjusted,facilitating mounting.This type of bearing is designed to achieve the maximum load rating capacity in a limited space.More sealed type four-row tapered roller bearings are used currently.Four-row tapered roller bearings(open type)comprise three cups,two cones,four rows of rollers,two cups spacers and one come spacer, or additional ,two seal ribs if sealed type.

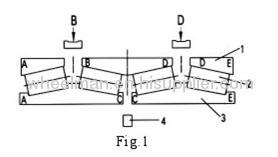

The clearance of four-row tapered roller bearing can be adjusted by two cup spacers and one cone spacer.This can assure required rotational precision and normal operation,and give a much longer bearing service life As shown in Fig.1,four-row tapered roller bearings can accommodate great radial load and axial loads in both directions simultaneously.Axial load in one directions carried by two rows of roller(row 1 and 3),then axial load in the other direction is carried by the rest rows(row 2 and 3).If bearing internal clearance is not suitable,axial load will only be carried by any one row of roller.Obviously,this situation will increase the pressure among rollers carrying load,cone and cup and eventually harm bearing service life.Therefore,bearing internal clearance must be checked when mounting.

Cage

Normally,stamped steel cage with pockets is used but for large dimension, machined solid in type cage is used.

Selection of clearance

The clearance of this type of bearing is determined by three spacers and can be achieved by adjusting spacer dimension.Take out all spacers and place cone and cup in turn.Apply afore on cups (marked AB and DE)and make every roller row closely contact with cone and cup,Measure the gap at BB,CC,and DD,the actual thickness of spacer.BB'CC",DD' are

Rolling Roll Bearings

There are two methods usually used to measuring the gap at BB,DD and CC.

First one is :place the bearing on bench(Fig.2),then take out spacer and apply a force on top cup.Force should be one or three times of bearing deadweight. Then measure the gap using measuring block or other instruments.

As shown in Fig.2,place cup and cone on the bench Manually rotate the cup and cone alternately.When rotation stop naturally,eliminate the misalignment between the cup and cone.Check the contact of rollers with cup with a feeler gauge of 0.02mm or 0.033mm to assure there is no misalignment between rollers and cup .Then place cup and cone continuously

Make sure roller end closely contact with cone rib.Finally apply a weight of Q.

When measuring ,check the gap at three places respectively every 90°.on bearing circumference and record the mean value of four readings.Then reverse the bearing and repeat foresaid steps.Take the mean value of two measurements as the gap at BB,CC and DD

Rolling mill Double-row Tapered Roller Bearings (axial load carried)

Main type is 370000comprising two single cups, one double cone and one cup spacer.

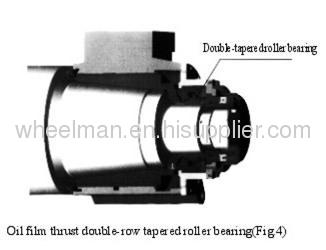

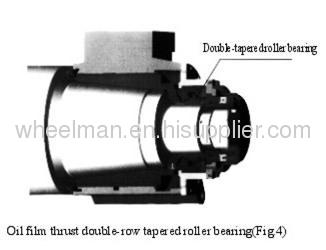

Contact angle is steep type(e≥0.67)and can carry larger axial load .This type of bearings is suitable for applications that only axial load exists or combined with a radial load smaller than the axial load carried This type of bearing is usually used as oil film thrust bearing(Fig.4)

Sometimes ,this type of bearing will has the cone with keys lot and no spacer.This type of bearing needs pretensioned and is mainly used on rolling mill roll neck.This is a compact type design with split cups facilitating mounting and demounting.

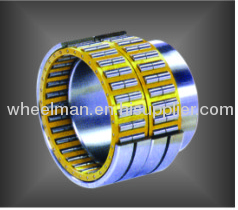

Four-row Cylindrical Roller Bearings

This type of bearing can carry heavy radial load and impact load .This type bearing is suitable for high-speed rotation and mainly applied on rolling mill roll neck .Main types of these bearing are FC,FCD and FXDP.

Screw down Thrust Tapered Roll Bearings

This type of bearing is used on screw down ball screw end .

There are two types:TTS and TTSV, They are all full component type cylindrical roller bearings.The profile of inner ring is designed with concave or convex spherical shape suitable for ball screw end.Inner ring has a central handle hole and bolts.Outerring also has bolts .ZWZshould be consulted if special ring shape.boundary dimensions and precision are require

Rolling Roll Bearings

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!